All-Terrain Prosthetic Ankle-Foot

Design Project • CAD • FEA • Prototyping

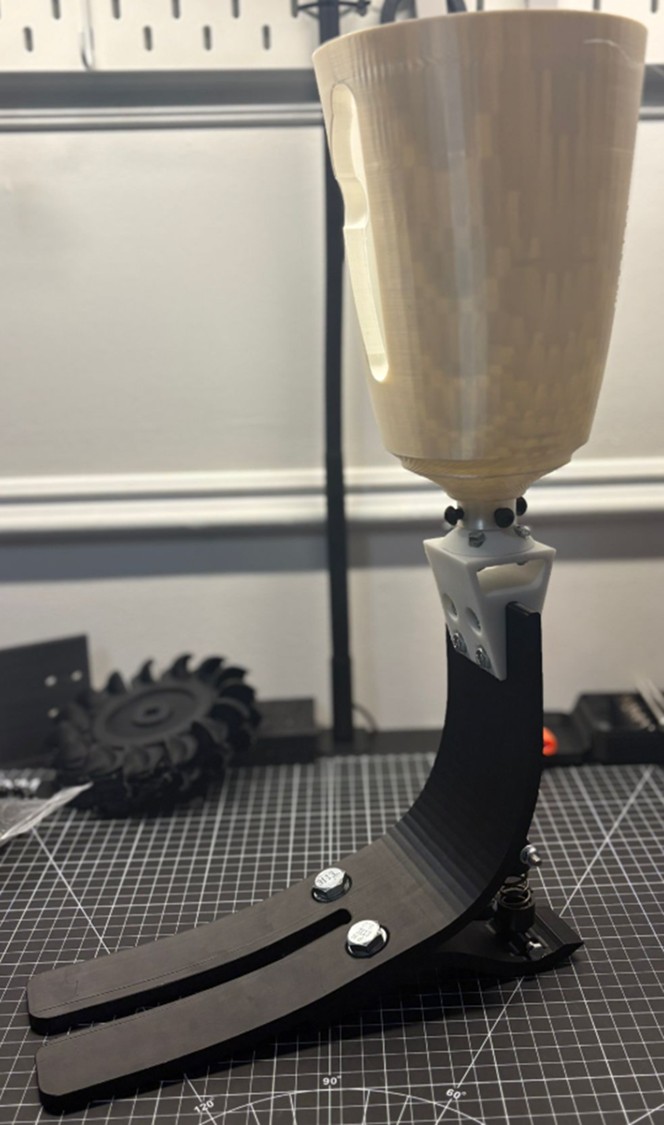

Design & Prototype

Project Overview

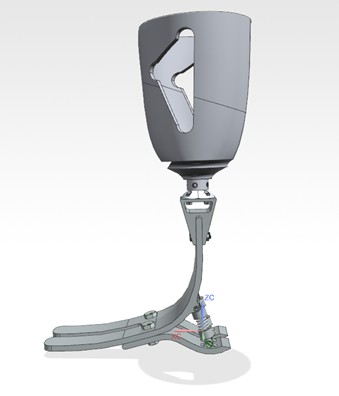

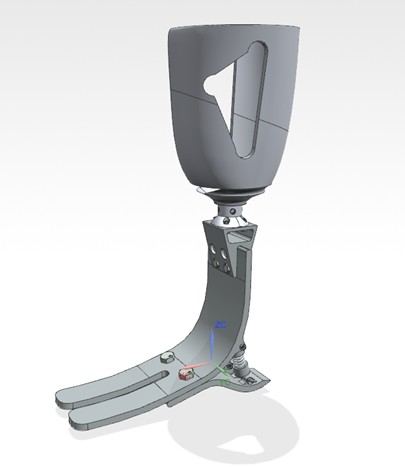

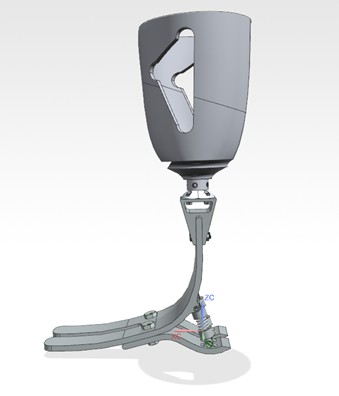

Designed and validated a fully mechanical, dual-axis ankle-foot prosthesis to improve stability and adaptability during walking on uneven terrain. The system provides natural ankle motion without electronics, prioritizing reliability, manufacturability, and cost-effectiveness.

The design focuses on passive mechanical compliance to accommodate real-world terrain variations while maintaining structural integrity under repeated physiological loading. All components were developed with rapid prototyping and scalability in mind.

Engineering Objectives

- Enable controlled dorsiflexion and plantarflexion during gait

- Accommodate inversion and eversion caused by uneven terrain

- Ensure structural safety under cyclic body-weight loading

- Design for ease of manufacturing and assembly

My Technical Contributions

- Developed parametric CAD models and full mechanical assemblies

- Defined load paths, joint interfaces, and component constraints

- Selected materials based on strength, stiffness, and manufacturability

- Prepared engineering documentation and design rationale

Key Design Decisions

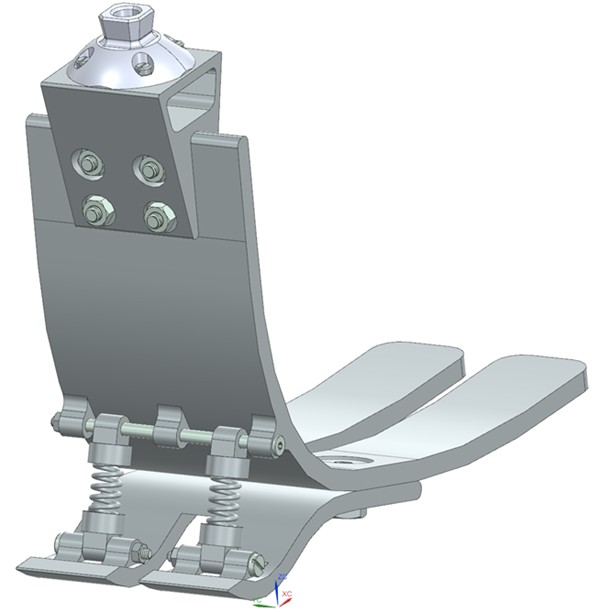

- Dual-degree-of-freedom architecture for realistic ankle motion

- Spring-based restoring mechanisms to maintain neutral alignment

- Modular design enabling rapid iteration and testing

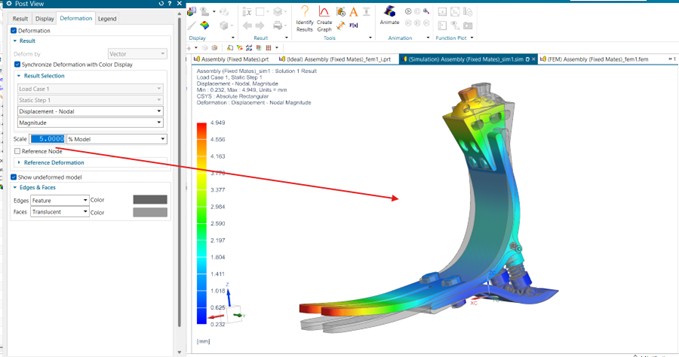

Engineering Analysis & Validation

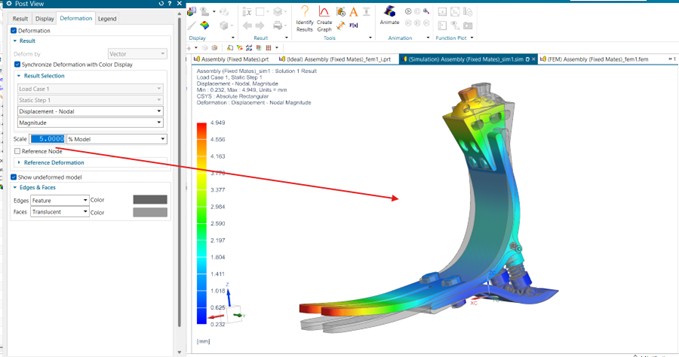

Finite Element Analysis (FEA) was conducted to assess the structural performance of critical load-bearing components under representative walking loads.

Analysis Setup

- Applied vertical and angled loads simulating stance-phase loading

- Boundary conditions defined at pylon and ground-contact interfaces

- Material models for PETG and rigid photopolymer resin

Results

- Peak stresses remained below material yield limits

- Deflections stayed within acceptable ranges for gait stability

- Identified stress concentrations for future geometric refinement

Manufacturing & Testing

Manufacturing Methods

- FDM 3D printing (PETG) for structural foot components

- SLA resin printing for precision ankle housing features

- PLA components for non-load-bearing elements

- Standard fasteners and mechanical springs

Prototype Evaluation

- Manual load testing to assess articulation and compliance

- Observed inversion and eversion response on uneven surfaces

- Compared physical behavior against analytical expectations

Outcomes

- Validated stable dual-axis motion without electronic control

- Confirmed structural robustness under realistic loading

- Established groundwork for future fatigue and gait-cycle testing